High Quality Water Well Screen

The Runze@ water well screen consists of a screen pipe with two connectors at each end of the screen pipe. The screen pipe is made by winding cold-rolled wire, approximately triangular in cross section, around a circular array of the longitudinal support rods. The design of the Vee-Wire screen allows it to adapt perfectly to the aquifer formation:

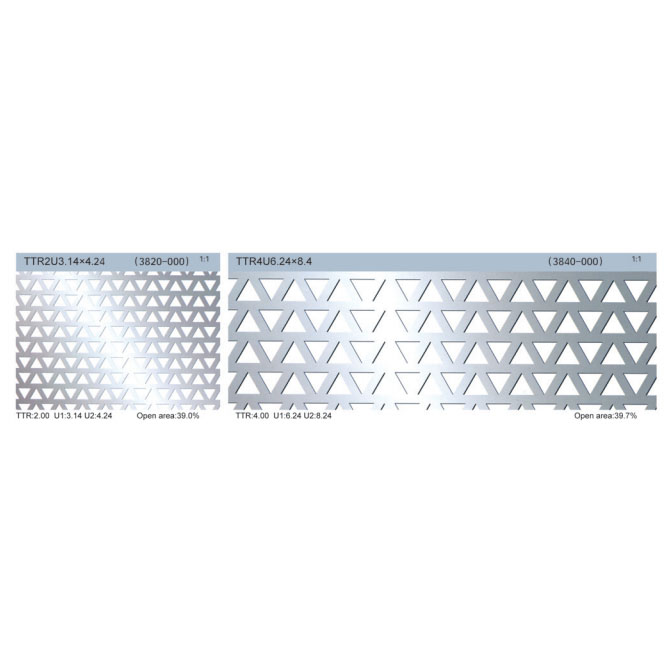

The sizes of the slot and the Vee-Wire determine the screen' s open area.

The shape and height of the Vee-Wire section and the screen diameter determine its collapse strength.

The number of support rods and their section surface determine the tensile strength of the screen.

The shape of the Vee-wire means that the slot opens inwards. This means that particles not able to pass through the slot will have only two points of contact, one on either side. This implies that with this design of screen the slot are non-clogging.

Slot sizes

Between 0.1 and 5mm.

Stainless steel 304 and 316 and 316L. Special corrosion-resistant alloys are also available for adverse conditions.

By using a continuous-slot screen, savings can be made in pumping costs. Lower through-slot velocities mean that pressure drops are minimized hence:

Drawdowns are reduced.

Less energy is needed for pumping.

Flow rates are increased.

Less sand in the water means less wear on the pumps.